The Structured Failure Management feature is used to define, configure, report and analyze failure related data in IFS Maintenance. The main object in the definition is the item class, which is used to hold the data related to a certain type of equipment. Item classes can be arranged in a hierarchy in order to facilitate inheritance from higher level classes. For example, a parent item class named General Pump can have child item classes named Centrifugal Pump and Diaphragm Pump:

- General Pump

- Centrifugal Pump

- Diaphragm Pump

Some definitions that are general to all pumps can be defined on the General Pump level, while those definitions that are specific to a certain type of pump can be defined on a lower level class, please refer to the section Propagation of Definitions for more information.

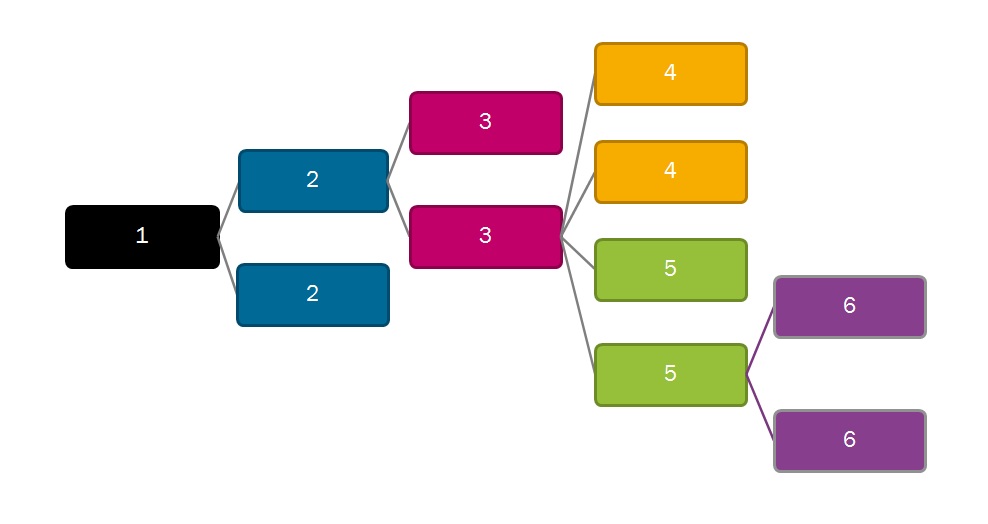

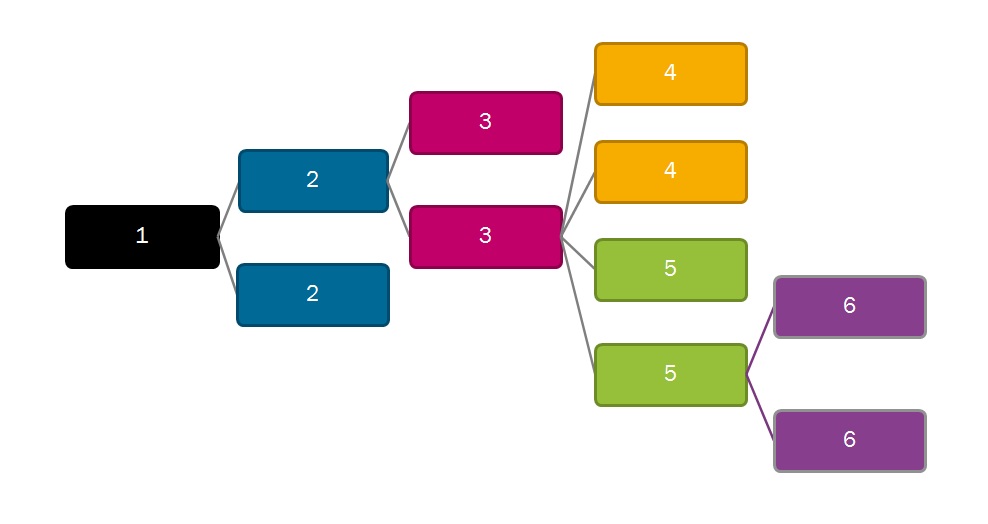

An item class can hold the following types of data, as shown in the diagram below:

Diagram 1 - Failure Analysis Data

Propagating definitions is performed to copy attribute definitions from a parent item class to child item classes. This is useful as general attributes can be defined on general item classes and lower levels can inherit them instead of entering them separately for each child item class. This feature greatly reduces the definition work and subsequent data maintenance work.

Once propagated, if failing components or functions which are already used on a work order are deleted from a parent item class, they will be deleted from the parent, but will remain on the actual item class used on the work order and will be displayed as native attributes on the item class after they are propagated again. Please note that the information on the work order will not be deleted.

Item classes can be connected to equipment objects, parts, object types, linear asset segments, linear asset objects, segment types, linear asset types, tool/equipment objects and tool/equipment types. When a work order is registered on an equipment object, a linear asset object or a tool/equipment object, the item class will automatically be retrieved to the work order, given that it is connected as stated previously. The priority order for an equipment object; first there will be a check against the equipment object, then the part and finally the object type. The priority order for a linear asset; first there will be a check against the linear asset segment, then the linear asset object itself, then the segment type and finally the linear asset type. The priority order for a tool/equipment object; first there will be a check against the tool/equipment object and then the tool/equipment type. Also item classes can be entered or modified on each work order manually.

In fault reporting and entering service requests,

the item class will be used to filter symptoms that are relevant to the type of

equipment. In work order preparation, applicable standard jobs/corrective

actions are filtered down based on the item class and symptom. In work order

reporting, the item class is used to filter down applicable values for fault

types, causes and functions. In analysis, item classes can be used in

information sources, for example with IFS Business Analytics.