The visualization for the machine availability category shows graphical information that makes it possible for the Manufacturing personnel to know the allocated machine hours for their shop orders and shop order operations, so that they can reschedule, split, and merge shop orders and reschedule operations.

For a general description about Manufacturing Visualizer refer About Manufacturing Visualizer.

Specific descriptions for each machine availability chart can be found using the links below:

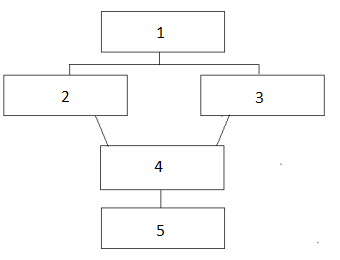

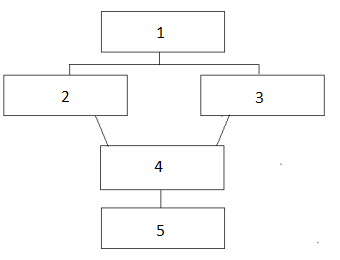

Machines can be arranged in a structure comprising sites, production lines, departments, work centers and resources. Each site has a number of production lines and departments. Work centers can be connected to production lines and departments. Resources are connected to work centers.

Figure 1 - Machine Structure

1 - Site

2 - Production Line

3 - Department

4 - Work Center

5 - Resource

The machine load categories are described in the table below.

| Load Category | Description |

| Not Loaded | The resource has capacity, but has not been assigned any work for the time period. |

| Partially Loaded | The machine has excess capacity that can be utilized.

Available - The total amount of available capacity per workday. This value is used when scheduling operations with the standard operation scheduling function. When available quantity is calculated, the system considers both the efficiency specified for each resource and any value specified in the Utilization field. The available capacity is calculated as: Available Capacity = S (Hours Available * Efficiency) * Utilization Theoretical Quantity = S (Hours Available * Efficiency) |

| Fully Loaded | The resource has been fully assigned. |

| Unbalanced | An unbalanced situation indicates that that there is unutilized capacity in a particular resource while another resource is overloaded and the workload can be balanced by splitting the work between the resources. |

| No Capacity Load | The resource has been assigned work on a day without capacity. |

| Overloaded | The resource has been assigned work exceeding its maximum capacity. |

| Past Due | The load that was due in the past that has not been completed as yet. The site date is considered as the current date when calculating the past due load for the time period regardless of whether the information is grouped by days or weeks |

Note that machine capacity must have been calculated for the site using Calculate Work Center Resource Capacity dialog box in order to receive a correct load categorization. To be able to visualize loads other then shop order, capacity requirements planning must be performed for the site using the Perform CRP dialog box.

There are several different load sources that are displayed in the machine visualization. Definitions for each of the load sources are as follows:

Planned: The machine load from shop orders in the Planned status.

Released: The machine load from shop orders in the Released status.

Started: The machine load from shop orders in the Started status.

Parked: The machine load from shop orders in the Parked status. The load will only be displayed in the visualization if the parked shop order has the Include as Load check box selected.

Maintenance: The machine load from work orders execution time. I.e. time between planned start and planned completion.

Unreleased DOP: The expected machine load for unreleased DOP orders, when they are released.

Requisitioned: The expected machine load for shop order requisitions, master schedule and production schedules, when they are converted to shop orders.

Promised: The expected machine load for interim orders from capability checked customer order lines for CBS and APB enabled sites. When the customer order will be released, this machine load will be converted to shop order machine load.

Resource Break: The machine time for resource break connected to work center for CBS and APB enabled sites. Capacity will be booked for the resource break.

When you right-click on one or several selected segment(s) you will get several navigation options. You could either navigate to another relevant visualization chart, or to the relevant page in the application. When you navigate in this manner, the new visualization or page will be filtered to only show the objects selected.

The following navigation possibilities are available in the charts, if applicable.

Navigation:

Charts can be published so that the chart is used as a master and changes in one chart are reflected in others. The following parameters are published from each chart.

| Publishing Chart | Parameters | |||||||

| Work Center | Work Center Resource | Date Range | Work Day | Shop Order | Shop Order Operation | CRP Order Reference | ||

| Machine Load Summary | Yes | Yes | Yes | Yes | No | No | No | |

| Machine Load in Standard Hours | Yes | Yes | No | Yes | No | No | Yes | |

| Machine Operation Load in Standard Hours | Yes | Yes | No | Yes | Yes | Yes | Yes | |

| Machine Load | Yes | Yes | No | Yes | No | No | No | |

| Shop Order Machine Load | Yes | No | No | Yes | Yes | Yes | No | |

When the chart is set up as a subscriber, it is possible to subscribe to the parameters below for the given chart set up as publisher. To be able to subscribe to a parameter, another chart needs to be set up as publisher and that chart must be able to publish the parameter.

| Subscribing Chart | Parameters | ||||||

| Work Center | Work Center Resource | Date Range | Work Day | Shop Order | Shop Order Operation | Labor Class | |

| Machine Load Summary | Yes | Yes | No | Yes | Yes* | Yes* | No |

| Machine Load in Standard Hours | Yes | Yes | Yes | Yes | Yes* | Yes* | No |

| Machine Operation Load in Standard Hours | Yes | Yes | Yes | Yes | Yes* | Yes* | No |

| Machine Load | Yes | Yes | Yes | Yes | Yes* | Yes* | No |

| Shop Order Machine Load | No | Yes | No | Yes | Yes | Yes | Yes |

* When subscribing to shop order and/or shop order operation this information will be translated into a work day, work center and work center resource. I.e. all the load on the specific day, work center and work center resource will be shown in the chart and not only the specific shop order/shop order operation published.